Refrigeration for developing countries

Practical Action

Solar refrigeration units of this kind, especially designed for vaccine preservation, are

commercially available. A system providing 60-80 watts of cooling is typically priced in the

range of £3000-5500. Replacement parts will tend to cost £500-1000 in the course of four

years of operation. Most of this cost will be in the replacement of batteries which are

designed to have a four year life but can fail in a shorter period if maintained poorly.

Replacement costs are considerably reduced if skilled, technical maintenance personnel are

available.

Combined heating/drying/cooling system

Because a refrigerator releases heat it can be used to raise temperatures in agricultural

processes like crop or spice drying. The cooling effect can be used to dehumidify the air

passing over the crop and the heating effect can be used to warm the air. In this, very high

efficiencies can be obtained (for instance up to 7 times as much useful energy produced as

required to drive the device). Such efficiencies are commonly met in timber drying plants

using these principles. Practical Action is developing low cost methods of utilizing this effect,

with respect to drives from small hydro turbines or from steam or diesel engines.

A second example is the use of heat from a refrigerator (also known as a heat pump, exactly

the same machine) to help sterilize milk, while the same refrigerator cools the milk to

preserve it.

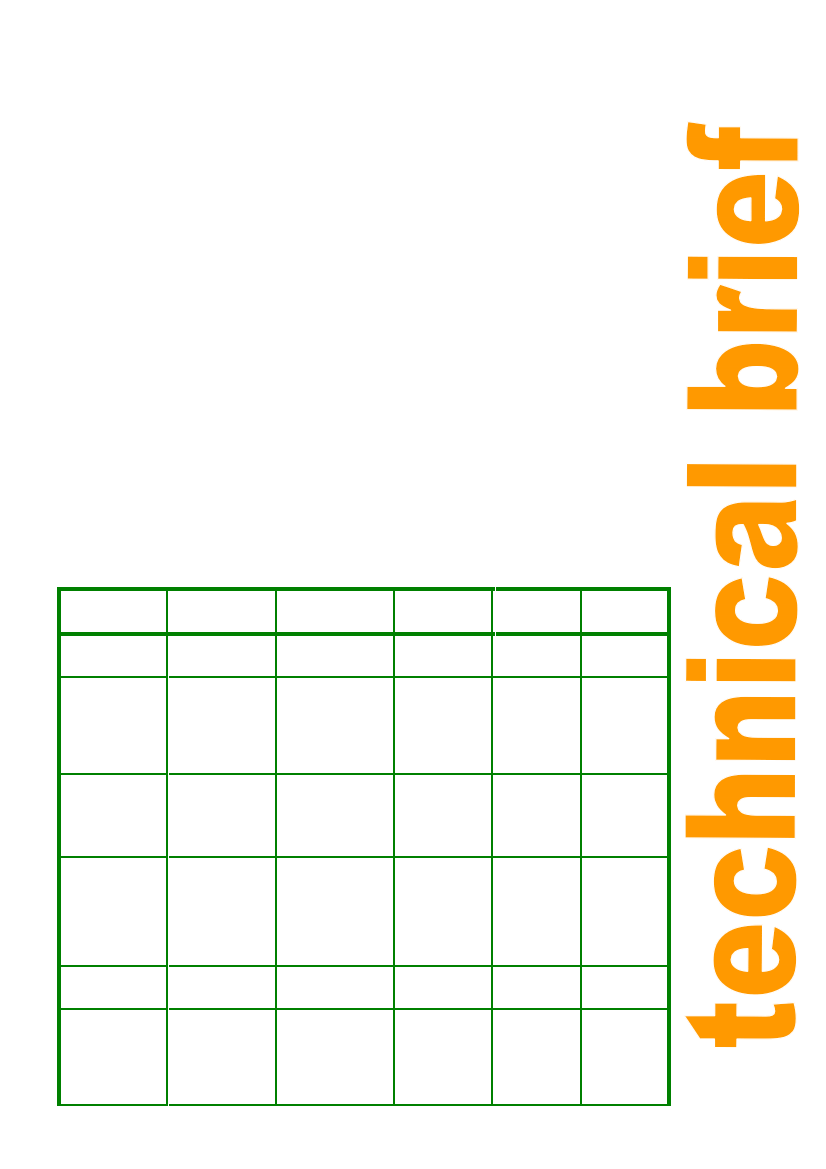

Choosing the system

In order to decide which refrigeration system to adopt for a particular purpose, it is necessary

to consider the ongoing inputs required by each system. Table 1 lists the various systems and

the inputs required for each. The choice of system is based on the foreknowledge that all the

necessary inputs will continue to be available in the locality of the fridge. The mistake is

often made of installing a unit with a relatively low purchase cost which later ceases to

function through lack of necessary inputs.

COMMENT

ENERGY SOURCE

PERSONNEL

SPARE

PARTS

10 YEAR

TOTAL COST

MECHANICAL

COMPRESSION

Grid

Electricity

Grid electricity. Cost Maintenance:

Source of

Purchase

available for other of connecting/

skilled

parts may be cost,

purposes, e.g.

transforming can be personnel.

distant.

electricity,

lighting, flaking of high.

Supply may

personnel,

ice. be uncertain. replacement

parts.

Diesel

Electricity

available for other

purposes, e.g.

lighting, flaking of

ice.

Diesel generator

Maintenance:

skilled

personnel

permanently on-

site.

Source of

parts may be

distant.

Supply may

be uncertain.

Purchase

cost, diesel,

replacement

parts.

Solar photovoltaic

Expensive.

Electricity

available for

lighting,

communications,

temperature

control.

Irradiation of 10-20

MJ/day/m². Long

cloudy periods

problematic.

Skilled

personnel

permanently

available.

Battery life 2-

4 years.

Control

electronics

can fail.

£3500-6500

for 60-80 W

cooling,

includes

replacement

costs.

SORPTION

(HDCs)

Conventional

5

Well known in the

field.

Gas/kerosene

quality must be

adequate.

Burner parts,

wick

adjustment, etc.

Replacement

of burner

parts routine.

£1000-2000

for 60-100 W

cooling and

small

maintenance

cost.